RT9 CASE | NCE OY – BABCOCK OG WILCOX VOELUND

Lisbjerg Forbraending

TASK AND SOLUTION

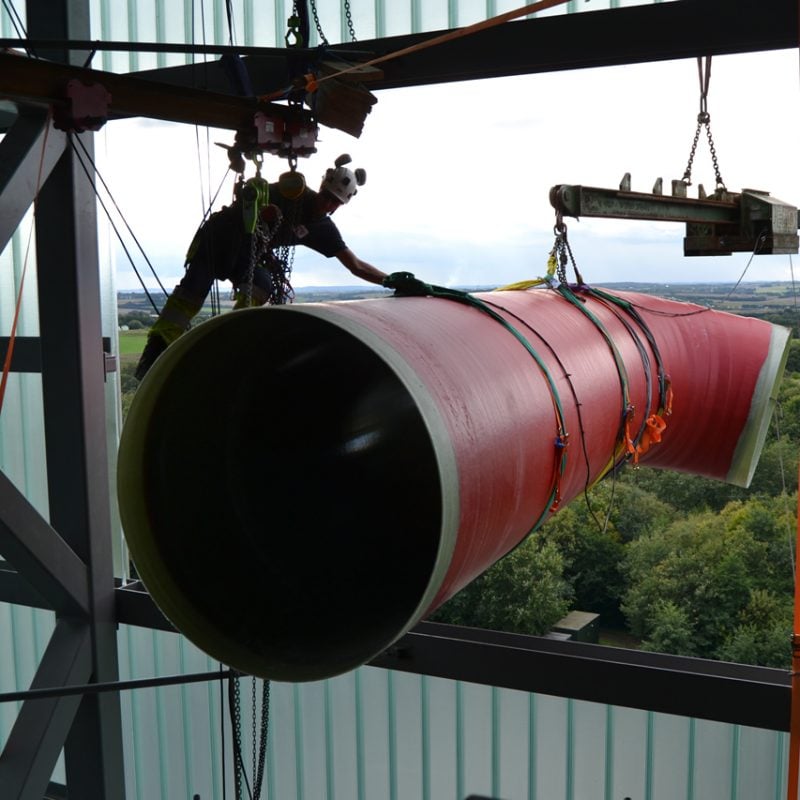

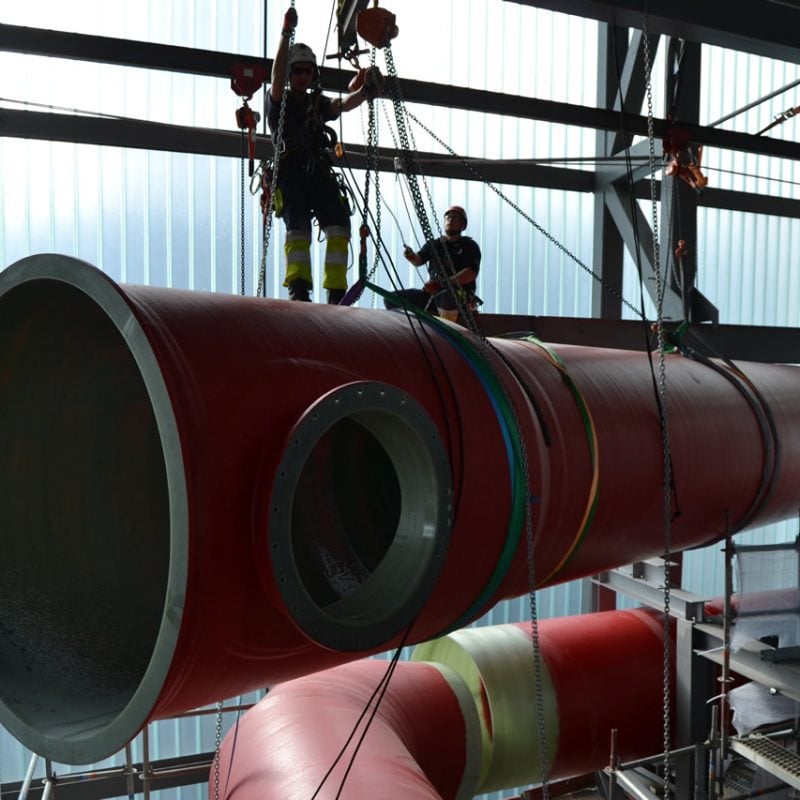

In connection with new biofuel, new composite pipes had to be laid all around the building from floor to ceiling. In total approx. 300 meters of composite pipe.

The task started with the installation of 70 meters of running rails at the top of the structure. The runners were used to transport the composite pipes from one end of the building to the other end and into the chimney. The running rails were rigged up in slings corresponding to the weight with which they would be loaded. On the running rail, trolley lines were mounted, which could move freely on the rail, and on which the pipes could then be transported.

Once the pipes had been transported to the area where they were to be installed, the pipes were lowered to the installation point using jacking gear and mobile cranes that could be moved around the building. Once the pipes were in place, a supporter was fitted and the pipes were connected to the system. The composite pipes were craned in by BMS through a hole in the facade.

PIPE SIZES

Diameter from 1.4 to 1.8 meters. Lengths from 6 to 12 meters – with and without bends. Weight from 800 up to 2,000 kg. per unit.

DURATION

The task was completed in 10 weeks. A five-week delay was made up for along the way, and the task was delivered at the agreed time.

REFERENCE

Andreas Snellmann, NCE OY

Lisbjerg Forbraending is a danish power station. This solution was a collaboration between two industries – “Rigger” and “Rope Access” – which made it possible to work with the pipes in all directions, regardless of where they were to be installed.

The solution made scaffolding and other equipment redundant – and saved the customer both time and money.

The solution demonstrated how over 25 years of combined experience and innovation can make impossible tasks possible and create big savings.

Contact us and hear more about which solutions we can offer you!

“We chose RT9 as our partner for the challenging flue gas duct project at Aarhus, as they could work safely and efficient without scaffoldings from ropes – saving us both money and time.

The collaboration with RT9 was very smooth and their innovative approach to the faced challenges to find cost efficient solutions was very well executed together with our experienced assembly team from NCE Oy.

With the joined skills from NCE Oy and RT9 the installation was a great success, and I can recommend their innovative services for future projects!”

Andreas Snellman, Project Manager, NCE Oy